Hydrogen electrolyzer cost is high due to noble metals. You can see all the international electrolyzer and fuel cell prices in the members area. While hydrogen is harvested in electrolysers oxygen is left over on one side of the membrane. For every liter of produced hydrogen half a liter of oxygen escape without use.

Table of Content about Oxygen from electrolysis

The oxygen problem with hydrogen appliances

Thinking of the difficulties of fuel cell, the oxygen supply through the ambient air is a challenge. The Oxygen percentage of ambient air can vary and the by-products like dirt and dust can harm the fuel cell efficiency. To run a hydrogen fuel cell with constant pure oxygen and pure hydrogen supply will lead to a great improvement of efficiency.

Also, for hydrogen combustion engines and simply burning hydrogen the nitrogen in the air is bad. Nitrogen oxides must be reduced from ambient air by AdBlue or urea addition.

Megawatt electrolyzer in Spain uses the by-product oxygen of electrolysis

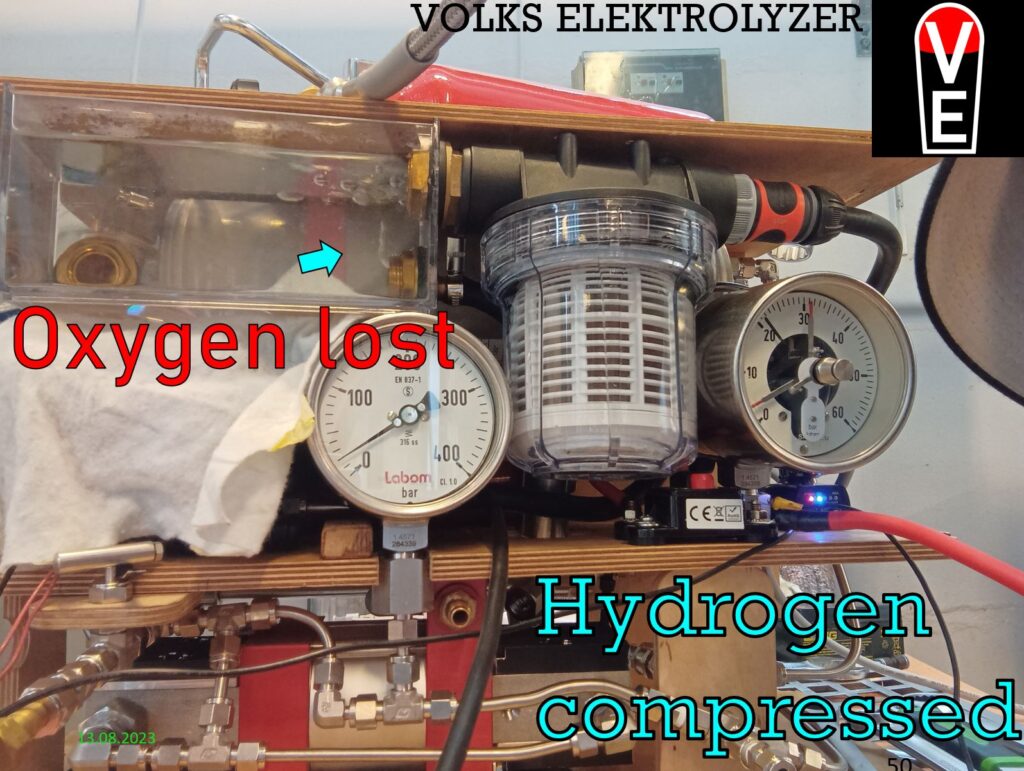

The spanisch company Iberdrola produces fertilizers with green hydrogen. They use the by-product oxygen for other industrial processes. Sadly till now, no electrolyzer manufacturer has made the oxygen to a usable resource. That is why VE is the first Electrolyzer Manufacturer with optional Oxygen use. The Oxygen from green hydrogen production is compressed into 300 bar cylinders ready for use in medical and metal applications.